Shaped Charge Liner Forging

As a leading shaped charge manufacturer, we pride ourselves on delivering high-quality, expertly engineered shape charges designed to meet the demanding needs of industries such as oil and gas, mining, and defense.

Powerful focused energetics for a host of industries

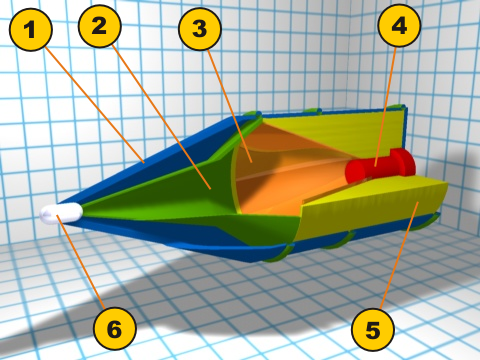

A shaped charge is an explosive charge shaped to focus the effect of the explosive’s energy. Different types of shaped charges are used for various purposes such as cutting and forming metal, initiating nuclear weapons, penetrating armor, or perforating wells in the oil and gas industry besides demolition of structures as well as in quarries to harvest precious materials from the earth. The military commonly refers to these as (HEAT) high-explosive anti-tank warheads frequently used in anti-tank guided missiles, rockets, gun-fired projectiles (both spun (spin stabilized) and unspun), rifle grenades, land mines, bomblets, torpedoes, and various other weapons.

Why Choose NWI Defense?

NWI Defense, formerly Northwest Industries, has been the US industry leader since 2012 in forging and machining shaped charge liners for our warfighters. At max demand levels in 2019 to 2021 NWI Defense has demonstrated forging capacity of 16,000 units per year complimented by ultra-precision machining capacity of 3,200 per year. The primary DoD platforms for NWI Defense have been Hellfire/JAGM and Javelin Programs of Record.

Our Expertise in Shaped Charge Liners

- Ultra-Precision Machining: Specializing in refractory metal forging and ultra-precision value-added machining, we transform billets of specialty alloy into near-net shapes that various industries rely on for strategic applications including, but not limited to oil & gas as well as military and defense.

- Hot and Cold Working: Our team of highly skilled technicians has mastered both hot and cold working of various refractory metals, ensuring the production of high-quality components for military, defense, and commercial programs.

- Controlled Processes: Leveraging our proprietary intellectual property, we manipulate and control dimensional criteria and recrystallization of preforms forged on our four mechanical forge presses.

- Proven Excellence: Our products ballistic performance are recognized as best in class, supporting the ever-evolving needs of industry, military missions, and academic research.

Advanced Capabilities and Benefits

- State-of-the-Art Equipment: Utilizing our standardized forging equipment, we ensure optimal metal flow and deformation for end products.

- Superior Quality: Achieve superior surface finishes and dimensional tolerances in a controlled, repeatable fashion.

- Scalability: Our processes are designed to scale up quickly and efficiently.

- Cost Efficiency: Reduce the overall cost of metal components while meeting or exceeding drawing requirements and achieving desired grain sizes.

Contact Us

With our proprietary processes and state-of-the-art capabilities, NWI Defense can help you achieve your shape charge liner forging projects. Contact our dedicated team today to discuss your specific needs and how we can assist you in achieving superior results.